Plants

Re-Mineralization Water Plant

Desalinated water is typically low in mineral content, hardness, alkalinity, and pH, necessitating re-mineralization before distribution to prevent corrosion and meet dietary needs. Chemicals like lime, calcite, and dolomite are added at 60 to 120 mg/L to enhance water quality. This process produces calcium carbonate or magnesium carbonate, forming a protective film inside pipes that prevents corrosion and increases water hardness, often referred to as addition of hardness.

Whole House Filtration System

A system that connects to your main water line, ensuring all water sources in your home dispense treated water for drinking, bathing, and other uses. It utilizes activated carbon to reduce chlorine and other chemicals in tap water, providing high-quality water throughout the house, unlike systems that only filter water at one point.

Water Softener Plant

Water softening involves reducing calcium, magnesium, manganese, and iron ions in hard water. This process occurs as water flows through a resin bed, where negatively charged resins attract and bind positively charged metal ions. The resins exchange divalent ions like calcium and magnesium with univalent ions like hydrogen, sodium, or potassium. The resin releases softer ions into the water, effectively softening it. Resins can also remove carbonate, bicarbonate, and sulfate ions while releasing hydroxyl ions, offering comprehensive water softening in a single system

Anti Scaling Plant

Anti-scaling equipment tackles lime scale issues in water systems, enhancing performance and reducing damage. This electronic water conditioner is effective in combating biofilm, scale, and bacteria without the need for excessive chemical use. Widely used in various applications like RO and MF membranes, municipal water, wastewater, and swimming pools, it improves plant efficiency, flow, and water quality.

De-Ionizer Plant

Deionizers utilize cost-effective ion exchange technology for water purification. These systems consist of two interconnected pressure vessels containing cation and anion exchangers to remove dissolved salts from water. Regeneration involves acid and alkali solutions to maintain performance. Deionizers come with necessary equipment for regeneration and monitoring water quality, suitable for diverse applications due to their range of capacities and flow rates

Reverse Osmosis Commercial Plant

Reverse osmosis effectively removes contaminants like heavy metals, bacteria, and 99% of total dissolved solids (TDS) to produce potable water. This process, popular in wastewater treatment and the food industry, involves pressurizing water through a semi-permeable membrane to separate impurities. The resulting purified water (Permeate) and concentrated brine (Concentrate) are produced, ensuring clean, safe water for various uses. The concentrate valve regulates the flow of feed water to control the concentrate stream and the resulting permeation

Reverse Osmosis System Domestic

Reverse osmosis uses a semi-permeable membrane to purify water by rejecting contaminants while allowing purified fluid to pass through. The process relies on pressure to push water through the membrane, effectively removing bacteria, salts, sugars, and other particles. It is an efficient method for water purification in domestic settings

Silica Sand Media & Granular Activated Carbon Plant

Water purification involves removing unwanted chemicals, materials, and contaminants to make water suitable for various purposes. Methods include filtration, sedimentation, biological processes like activated carbon filters, and UV light treatment. The purification process eliminates impurities like bacteria, viruses, algae, and dissolved particles, ensuring water quality for consumption and other applications

Ozone Generator

Ozone is an effective and environmentally friendly disinfectant widely used in water treatment. Its strong oxidizing properties and minimal environmental impact make it a popular choice, replacing costly and hazardous chemicals. Ozone's high oxidizing power allows it to eliminate contaminants in water rapidly, outperforming chlorine and bromine in killing bacteria, fungi, viruses, and parasites.

Chemical Dosing Pump

Chemical dosing pumps come in various capacities for different chemical treatment applications. They can function independently or integrate with system-based logic controllers. Chemical dosing is cost-effective for pretreatment, treatment, or post-treatment, with options like anti-scalants and anti-foulants to condition feed water in reverse osmosis systems.

Ultraviolet Sterilizer Unit (Commercial & Domestic)

Ultraviolet sterilizers use UV light to kill harmful microorganisms like bacteria and viruses in water, offering a chemical-free and low-maintenance solution for water disinfection. They are effective in safeguarding against waterborne illnesses without the need for chlorine or other chemicals

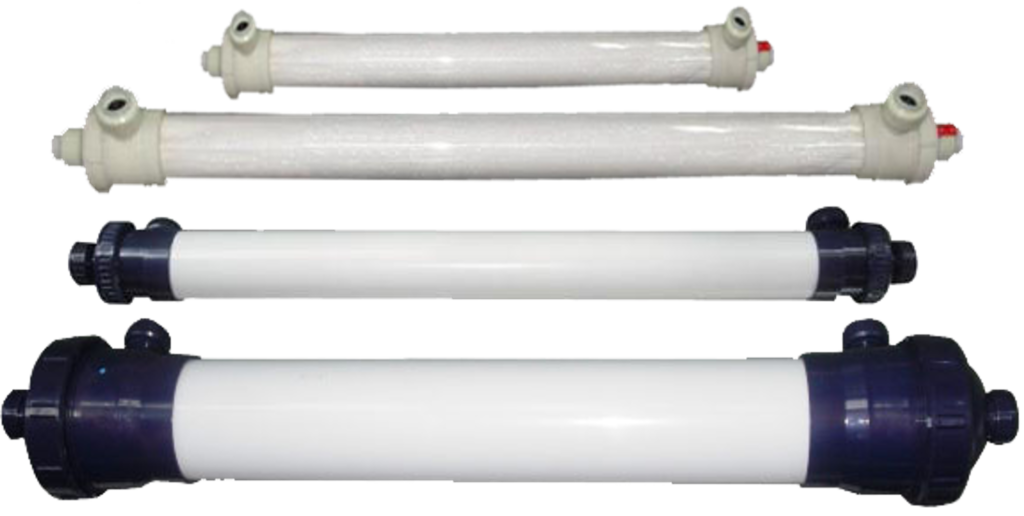

Ultra Filtration Membrane

Ultrafiltration (UF) is a pressure-driven membrane process that separates particulate matter from soluble components in water. UF membranes have pore sizes ranging from 0.01 to 0.10 um, effectively removing bacteria, viruses, colloids, and silt. Commonly used polymeric materials like polysulfide, polyether sulfone, polypropylene, and polyvinylidene fluoride are hydrophobic, impacting their cleanability with strong disinfectants like hypochlorite.

Dialysis Operated Plant

Water treatment for dialysis units is crucial and varies based on factors like water quality, source, architectural constraints, and budget. A comprehensive system for dialysis equipment typically includes pre-treatment, reverse osmosis, deionization, post-treatment, and recirculation. By employing Reverse Osmosis (RO) principles and incorporating a deionizer, the plant ensures water purity surpasses regulatory standards.

Swimming Pool Filtration Plant

Maintaining a clean and safe swimming pool involves proper chlorine and pH level maintenance to eliminate bacteria and algae. Filtration plays a key role in removing insoluble matter from pool water, ensuring clarity for aesthetics, hygiene, and safety. Chlorine is commonly used for disinfection in pools, effectively destroying harmful organisms and impurities that filtration may not capture